Intro to 3D Modeling and Printing Using Fusion 360

IEEE Concordia

A hands-on workshop teaching CAD fundamentals, 3D printing workflow, and print-in-place design — culminating in participants designing their own functional wire holder.

Overview

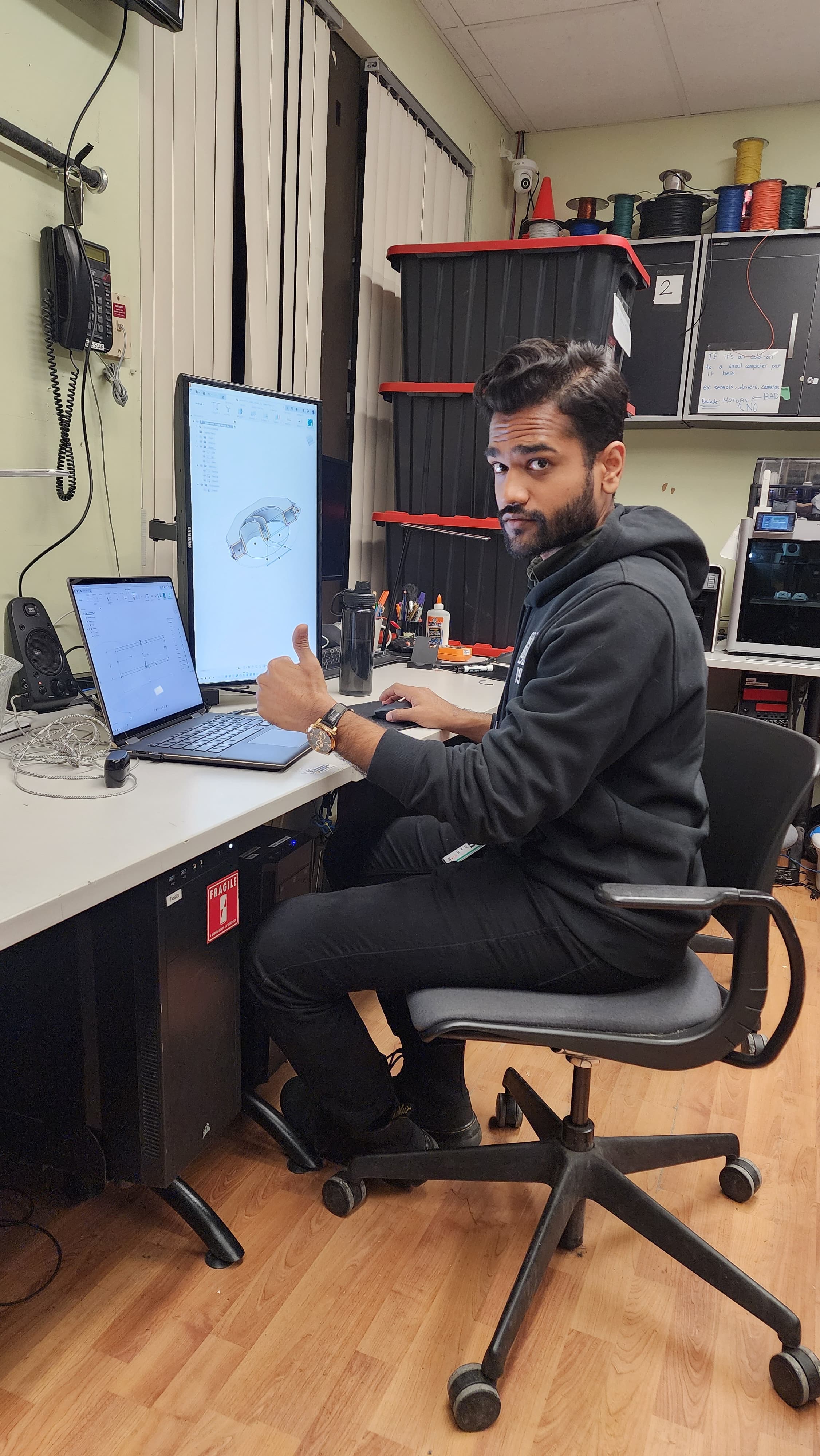

As VP Projects at IEEE Concordia, I volunteered to lead one of the bi-weekly technical workshops. This session introduced students with zero CAD experience to the full 3D modeling and printing workflow — from Fusion 360 basics to holding a finished print in their hands.

Workshop Details

| Duration | 3 hours | | Attendees | ~30-40 students | | Audience | 1st-3rd year engineering students, all skill levels | | Role | Sole instructor |

What I Taught

Fusion 360 Fundamentals

- Getting a student account set up

- Navigating the interface and workspace

- Sketching, constraints, and parametric modeling

- Extrusions, cuts, and basic operations

Design for 3D Printing

- Understanding tolerances and overhangs

- Print orientation considerations

- Support structures and when to avoid them

Slicer Software

- Introduction to slicing workflow

- Layer height, infill, and print settings

- Generating G-code for printers

3D Printer Basics

- How FDM printers work

- Common printer types and their tradeoffs

- Troubleshooting basics

Hands-On Project: Print-in-Place Wire Holder

The workshop culminated in a guided CAD session where every participant designed a functional wire holder with print-in-place hinges — an intermediate-level technique that demonstrates the unique capabilities of 3D printing.

By the end:

- Every student had a complete CAD file ready to print

- I came prepared with pre-printed examples so they could see the finished product

- Students learned that 3D printing enables designs impossible with traditional manufacturing

Why Print-in-Place?

I specifically chose this project because it showcases something you can't do with machining or injection molding. A hinge that prints as a single piece and works immediately off the bed — that's the kind of "aha moment" that gets people excited about additive manufacturing.